0 ₽

CheckoutAdvantages of the distillation column from CHZDA

Element of the distillation column "Gorilych" with a clamp is a product of serial production and factory quality, the reliability of the kit confirms the warranty obligations of the CHZDA (warranty period is 1 year). Food high-alloy steel, from which the device is manufactured, passes quality control in the company's own laboratory, so Gorilovich has an unlimited lifespan. The refrigeration unit is the dimromot refrigerator, tested for centuries, with a spiral tube inside. This is one of the best options for rectification of alcohol, since it provides the maximum contact area between the cooler and alcohol vapors. The seat under the thermometer will allow to control the reflux process without visual control over what is happening in the column.

The productivity of the element of the distillation column "Gorilych" with a clamp reaches up to 500 ml / h, which is confirmed by real feedback from the owners. It does not matter - what to use as raw materials, the output will be pure alcohol, from which you can prepare a reference home-made vodka, any kind of tinctures and liquors.

The low price of the element of the distillation column "Gorilych" with the clamp allows you to order it to upgrade an existing set of equipment (for example, a distillation cube for distillation). If this is the first experience with modular devices with clamp connections, you can add all associated accessories (clamps, gaskets, etc.) to the order.

The device is indicated for acquisition by those who value good and pure alcohol without a typical "moonshine" aftertaste and a cloudy color. In fact, the vodka, prepared from alcohol on the column "Gorilych", will be able to win by taste qualities the majority of positions in supermarkets in the middle price range. In addition, inexpensive rectified alcohol can be used for medical or technical purposes.

Register to leave a review about the product and earn reward points!

There are no reviews for this product.

1. Unpack the packed distillation column "Gorilych" and remove all packing materials.

2. Remove traces of factory treatment with water and detergent and rinse with clean water.

3. Fill the distillation cube with a small amount of pure water, collect the packed distillation column "Gorilych", and do not connect the hoses to supply water for cooling to boil for 30 minutes.

4. Disassemble the system, merge the remaining water from the distillation cube and column.

1st haul

5. The volume of primary wort should not exceed 3/4 of the volume of the distillation cube. It is recommended to use clarified primary wort, pre-filtering it from the suspensions of fermentation products. When using thick brews, the distillation process is carried out with individual modes of adjusting the parameters of heating the distillation cube and adjusting the supply of cooling water. The final regulatory indicators when using thick bogs may differ and will be individual, depending on the particularly used thick wort.

6. Primary wort is poured through the neck into the distillation cube.

7. The recommended volume content of alcohol in the original wort is from 10% and higher.

8. After connecting the cooling hoses to the reflux nozzles, check for tightness of their connection, briefly putting water in the hoses.

9. Stop the connection of the reflux condenser with the atmosphere.

10. Do not install the "Hoffmann" clip on the product collection hose.

11. Put the packing distillation column on the heat source and set the heating power to the maximum value (in order to shorten the heating time of the distillation cube)

12. After reaching a temperature reading of 70°C on the thermometer, turn on the water supply for cooling. Strongly not necessary, enough laminar flow of water (without bubbles of air in the hose), approximately 1 liter / min.

13. When the values on the thermometer are reached at the upper point of the collar 76-77°C (the scatter is due to the measurement error), low-boiling fractions (heads) will begin to distill. Approximately 1-2% of the volume poured into the distillation cube of a water-alcohol solution (if the primary wort is on sucrose) or 2-3% (if the primary wort is on fructose).

14. Then the collection of raw alcohol begins. Do not forget to use a silicone tube to collect the product, in order to avoid unnecessary evaporation of alcohol into the air during collection.

15. As the alcohol content in the primary wort decreases, the thermometer readings on the distillation cube begin to rise, down to 96 ° C - these are the regulatory indicators.

16. If the alcohol content in the brew is less than critical, the distillation process slows down automatically, expressed in a sharp drop in the intensity of the dropper, until the caprolling of the product stops. The temperature on the thermometer at the top of the packed column (under the reflux condenser) begins to fall - fall below 73°C. This indicates the automatic termination of the first distillation process.

17. Follow the thermometer readings on the distillation cube. If the reading exceeds 98°C, turn off the heating source and wait for the distillation column to cool down, disassemble it to perform a revision to find the clogging.

2nd haul

18. Wait until the distillation column cools down after the first distillation, disassemble it, remove the residues of the primary wort, formed reflux and rinse the column with water.

19. Reassemble the packed distillation column.

20. Having connected cooling hoses to the reflux condenser fittings, check for tightness of their connection, briefly putting water in the hoses.

21. To adjust the strength of alcohol and to achieve their maximum possible values, use Hoffmann clips or another similar valve on the product collection hose.

22. The Panchenkov RPN or other fillers should fill the entire volume of the column to achieve maximum efficiency of the rectifier.

23. After the first distillation, the raw alcohol obtained is diluted with water to 20-25% of the volume content of alcohol and poured the resulting aqueous alcohol solution into the distillation column of the distillation column.

24. Connect the connection of the reflux unit to the atmosphere with the atmosphere.

25. Put the rectification column on the heat source and set the heating power to the maximum value (in order to shorten the heating time of the distillation cube)

26. When the temperature reaches 70°C on the thermometer, turn on the water supply for cooling. Strongly not necessary, enough laminar flow of water (without bubbles of air in the hose), approximately 0.7 - 1 liter / min.

27. When the values on the thermometer are reached at the upper point of the casing column 75 - 76°C (the scatter is due to the measurement error), low-boiling fractions (heads) will begin to distill. Approximately 100-150 ml (if the primary must on sucrose) or 150 - 200 ml (if the primary must on fructose) is selected.

28. Then the collection of alcohol begins. Do not forget to use a silicone tube to collect the product, in order to avoid unnecessary evaporation of alcohol into the air during collection. As the alcohol content in the primary wort decreases, the thermometer readings on the distillation cube begin to rise, down to 96°C - these are the regulatory indicators.

29. Using the Hoffmann clamp or the needle valve, adjust (reduce) the conduit in the product collection tube to achieve the highest possible strengths of the alcohol, while avoiding the complete cessation of the capless process. Monitor the volume content of alcohol in the jet with an alcoholometer or other devices designed for this purpose.

30. Observe the thermometer readings on the distillation cube. If the reading exceeds 98°C, turn off the heating source and wait for the distillation column to cool down, disassemble it to perform a revision to find the clogging.

Regulatory indicators *:

For the distillation column with a 12 liter distillation cube: approximately 0.6 liters of rectificate (in terms of 96% alcohol content) for 4 hours in a full cycle;

For a distillation column with a 15 liter distillation cube: approximately 0.9 liters of rectificate (in terms of 96% alcohol content) for 5 hours in a full cycle;

For the distillation column with 20 and 21 liter distillation cubes: approximately 1.2 liter of rectificate (in terms of 96% alcohol content) for 6 hours in a full cycle;

For a distillation column with a 30 liter distillation cube: approximately 1.6 liters of rectificate (in terms of 96% volumetric alcohol content) for 7 hours in a full cycle.

* Regulatory indicators may vary depending on the type and performance of the heat source, temperature and cooling intensity, temperature regimes, type and density of fillers used for the packed distillation column.

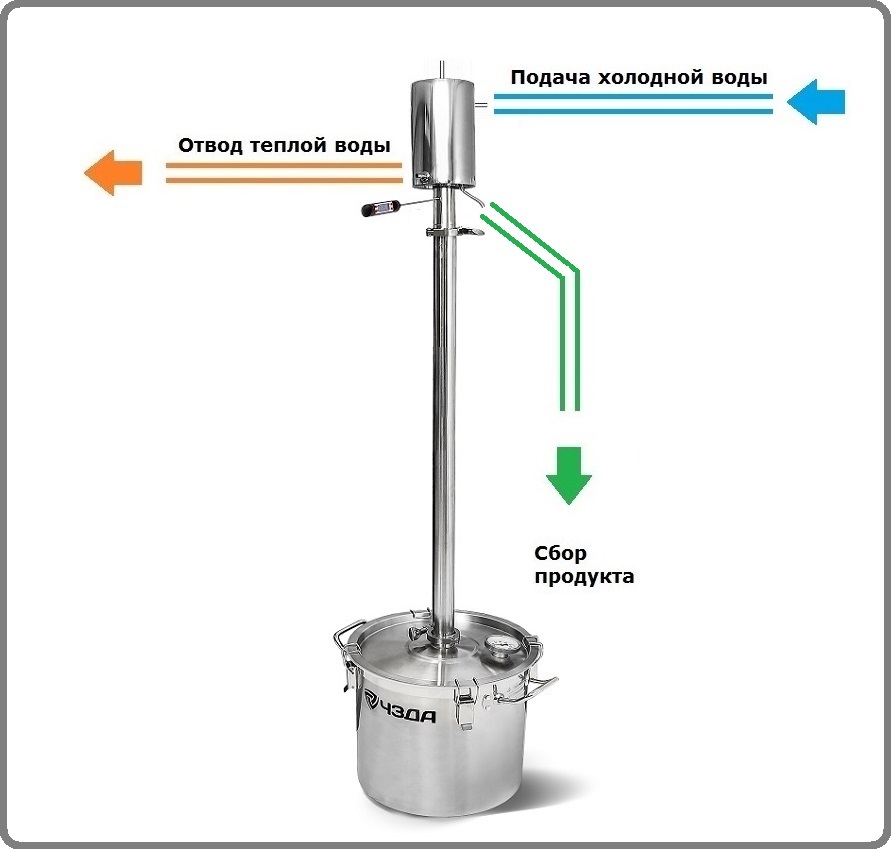

Connection diagram

Delivery of Gorilych products and related products.

You can buy any stills, brewing and distillation column "Gorilych" in our Internet-shop ChZDA and get your order in Chelyabinsk or in official representative offices in different Russian cities. The list of stores or points of delivery (PWZ) in the Chelyabinsk region is constantly expanding and the actual information on their addresses and office hours you can always find on the interactive map when ordering, or get the information you need from our consultants free by phone 8 (800) 775-90-83.

You choose your own delivery variant.

You can choose a convenient way of delivery of your stills "Gorilych" and other CHZDA products to Chelyabinsk. When ordering, specify the type of delivery and select any delivery point (PWZ) in the list or on the interactive map. We will take care of the rest.

Safe and cautious packing

Before shipping your order each kit of Gorilych stills is carefully inspected for any external defects, wrapped in bubble wrap, carefully and tightly packed in shipping carton and provided with all the necessary documents (bill of lading, passport, warranty card). During the whole process of delivery to Chelyabinsk region we always track the location of your order to notify the buyer on the arrival of the goods to receive them.

Up-to-date information on the location of the order

Due to advanced integration solutions in Chelyabinsk ZDA online store the buyer is always aware of where and at what stage his order is.

Online information in the personal cabinet about the order's progress at all stages;

convenient services on site to track the progress of the order;

Post and SMS-notification of changes in order status and readiness of goods for delivery;

Agreeing on a convenient time of delivery with the courier service.

Look first, pay later

Due to our courier service and long-term cooperation with reliable transportation companies, the customer in most cases (excluding Russian Post) can always open the package upon receipt of the order and make sure that the package is intact and the order is complete. And only if there are no comments, the buyer can pay for the received goods in the store, at the point of delivery or to the courier.

ChZDA store not only offers quality stills and distillers of its own production in Chelyabinsk region, but also the most comfortable, and most importantly, favorable conditions for the purchase in Chelyabinsk. You do not need to solve the question of payment when ordering products from our catalog because you can pay for the stillizer in any convenient way including:

Bank cards MIR, Visa, Mastercard, Maestro;

Payment through a bank branch;

Through a system of electronic money UMoneu;

Payment to the courier at delivery of the order;

Payment at the issuing point;

Payment by cash on delivery at the post office;

We also have unique ways of payment - by accumulated bonuses and a gift certificate. Take part in our promotional actions, accumulate bonus points and get our products with great discount.

Absolute protection for online payments

All payments for CHZDA goods are made online through secure service JuMoneu, so you can be sure that all information with payment data is guaranteed to remain confidential and secure and can not be used by unauthorized persons: payment service JuMoneu is protected by PCI DSS - a standard Visa and Mastercard. Payments are credited on the same day.

We wish you successful purchases!